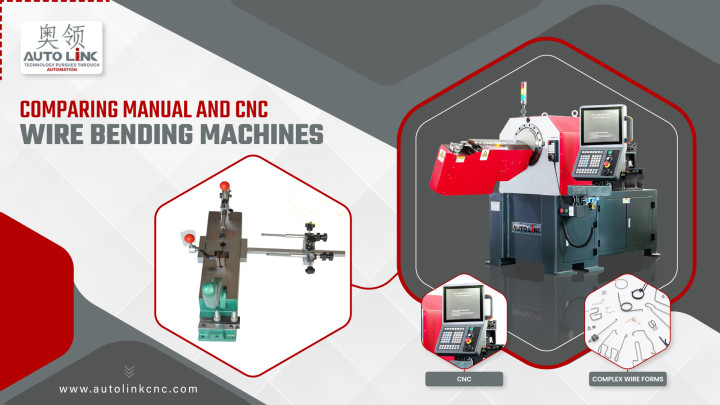

Comparing Manual and CNC Wire Bending Machines

There are two distinct approaches to shaping wire into specific forms for a variety of purposes, namely CNC wire bending and manual wire bending. Here are some distinguishing features between the two methodologies.

- Precision: CNC wire bending provides higher precision and accuracy than manual wire bending. The use of computer-controlled machinery allows for greater control over the bending process, resulting in consistent and precise bends.

- Complexity:CNC wire bending machines can handle complex shapes and geometries that may be difficult or impossible to achieve with manual wire bending methods. This makes CNC wire bending particularly useful for the production of complex wire forms such as springs, wire baskets, and custom wire components.

- Process: Manual wire bending involves the manual manipulation of wire into specific shapes using tools such as pliers and cutters. CNC wire bending, on the other hand, is a computer-controlled process that uses a machine to bend the wire into the desired shape.

- Production Speed:CNC wire bending machines can produce wire forms much more quickly than manual wire bending. The automation of the bending process and the ability to program the machine for multiple bends reduces the time required for each piece.

- Cost: The initial investment for a CNC wire bending machine is higher than manual wire bending tools, but over time, the increased efficiency and precision of CNC wire bending can result in cost savings for high-volume production runs.

When it comes to wire bending, CNC wire bending provides superior accuracy, intricacy, and efficiency than manual wire bending methods. Nevertheless, the most suitable approach would vary according to the particular necessities of each application.