How can I make customized spring making machine?

How can I make customized spring making machine?

Making a customized spring-making machine involves a tailored approach to meet your specific requirements. Below is a general outline of the steps you can follow:

1. Define Your Requirements: Determine the types of springs you want to produce, their dimensions, materials, and the production volume. Identify any unique features or capabilities you need in your machine.

2. Research and Gather Information: Study existing spring-making machines and technologies to understand their functionalities and limitations. Gather information on the mechanical, electrical, and control systems required for spring fabrication.

3. Conceptual Design: Based on your requirements, create a conceptual design of the machine. Sketch the layout, decide on the number of axes, and consider the mechanism for wire feeding, coiling, cutting, and other required operations.

4. Select Components and Materials: Choose appropriate components such as motors, bearings, guides, and electronic components. Opt for high-quality materials that can withstand the stresses and strains of continuous operation.

5. Detailed Design: Create a detailed design using computer-aided design (CAD) software. This design should encompass all the mechanical and electrical aspects of the machine.

6. Fabrication and Assembly: Manufacture or source the components according to the detailed design. Assemble the machine carefully, ensuring precision and alignment.

7. Electrical and Electronic Setup: Install the selected motors, sensors, and actuators. Design and implement the control system, either using microcontrollers or programmable logic controllers (PLCs).

8. Programming: Develop the software to control the spring-making machine. The program should interpret input data, regulate motor movements, and handle safety features.

9. Testing and Calibration: Conduct thorough testing of the machine with different wire materials and spring configurations. Calibrate the machine to produce springs within your desired specifications.

10. Safety Measures: Integrate safety features into the machine to protect operators and prevent accidents. Emergency stop buttons, protective covers, and status monitoring sensors are some examples.

11. User Manual and Documentation: Create a comprehensive user manual with operating instructions, maintenance guidelines, and troubleshooting procedures.

12. Training and Familiarization: Train the machine operators on how to use the equipment safely and efficiently.

13. Continuous Improvement: Plan for future enhancements and improvements based on feedback and evolving needs.

Remember that building a customized spring-making machine can be a complex project, and it's essential to have a good understanding of mechanical engineering, electronics, and programming. If you lack the expertise, consider collaborating with experts or seeking professional help to ensure a successful outcome.

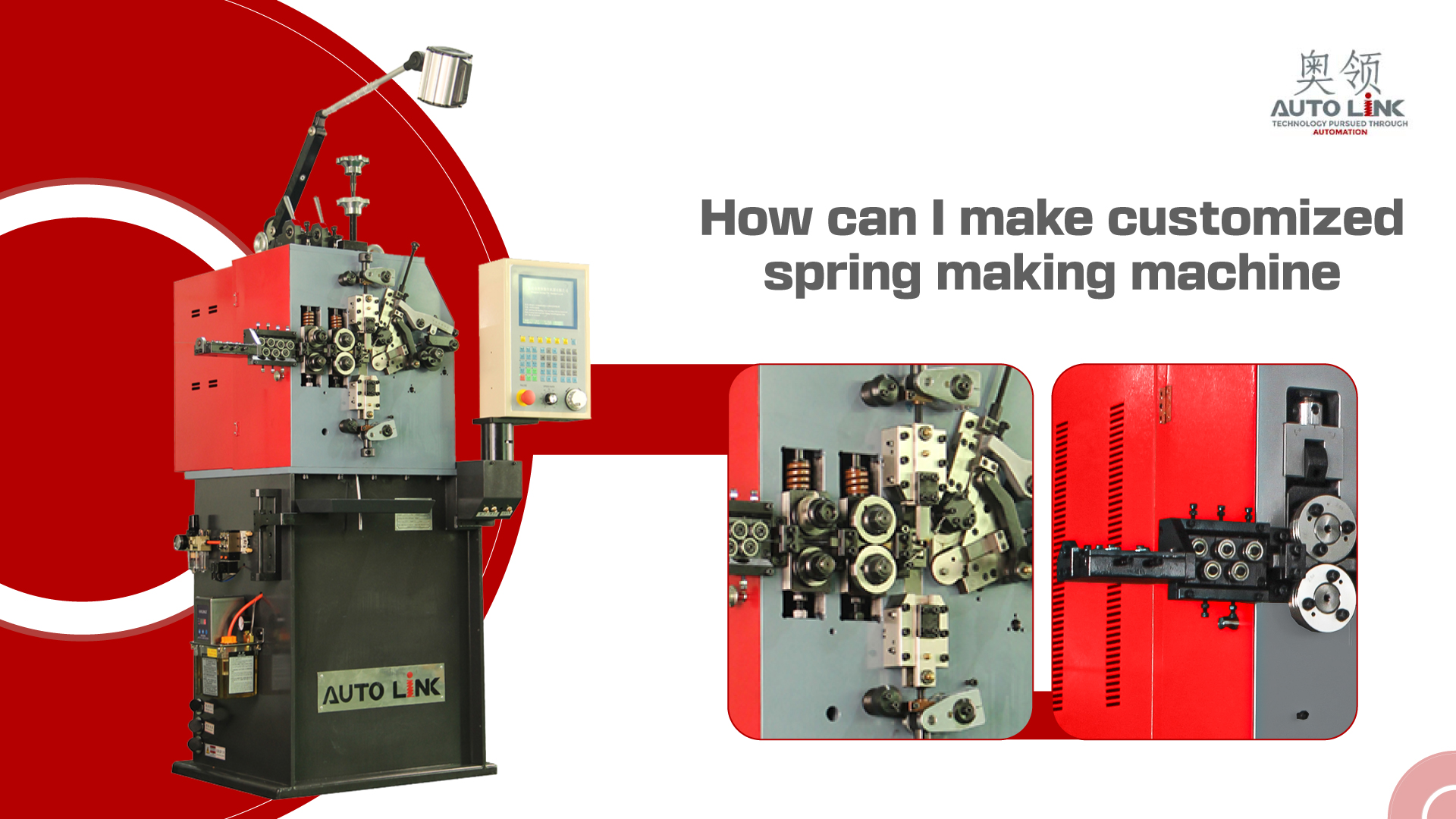

About AutolinkCNC:

AutolinkCNC is a leading company specializing in manufacturing customized CNC spring making machine. With a strong commitment to innovation, we strive to revolutionize the spring making machine by offering precision, versatility, and user-friendly solutions. Trust AutolinkCNC to shape the future of wire manufacturing through futuristic technology and exceptional quality.