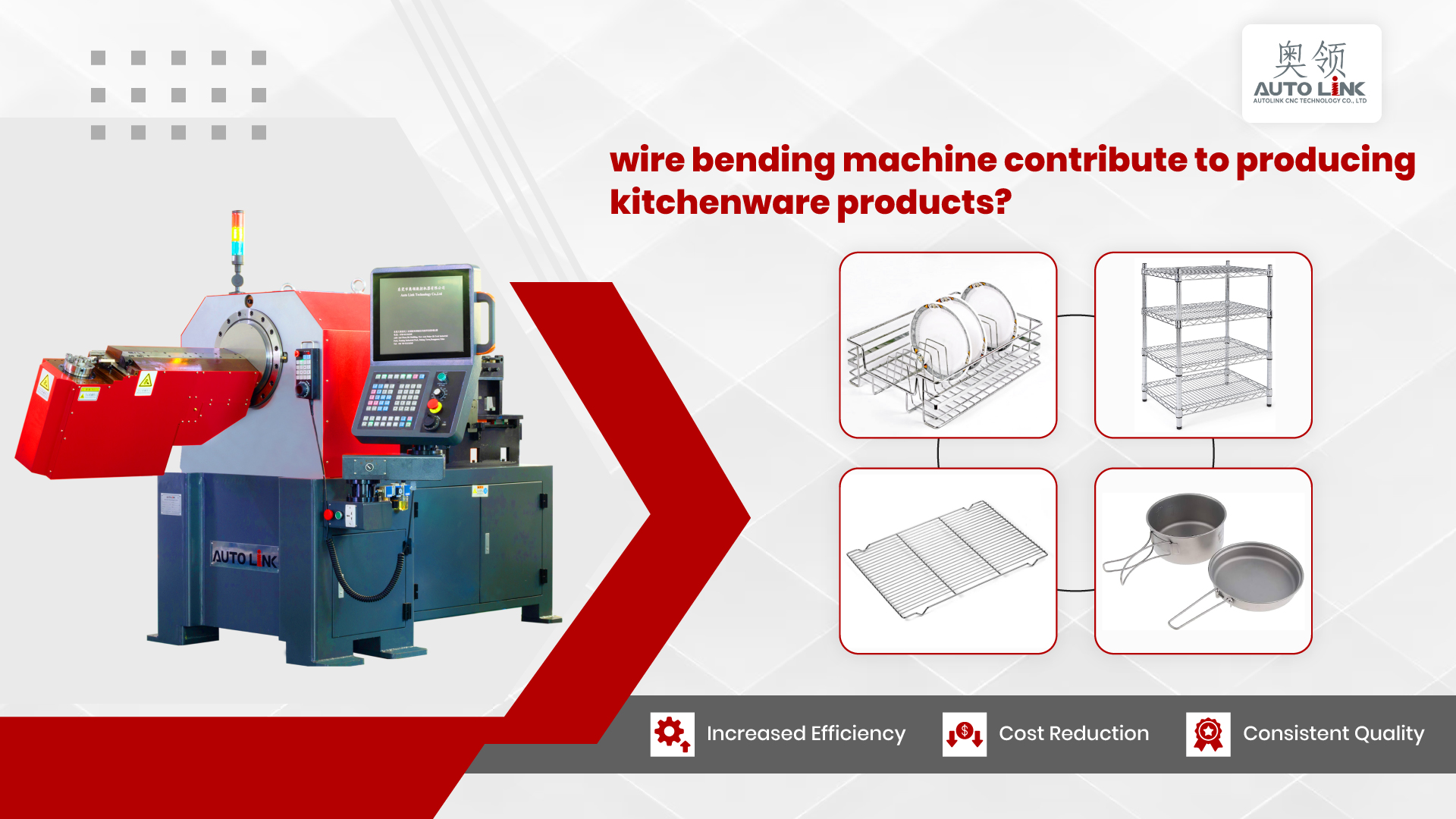

How does a wire bending machine contribute to producing kitchenware products?

A wire bending machine is an important tool in the production of kitchenware products, as it allows for the precise and efficient bending of wire into various shapes and sizes required for the production of kitchenware products such as Shelving, cooling racks, and baskets.

Shape and Size Customization: Wire bending machines can be programmed to be the wire into any desired shape and size. This enables kitchenware manufacturers to create customized products according to specific customer requirements

Increased Efficiency: The use of wire bending machines in the production of kitchenware products increases efficiency by reducing manual labor and increasing production speed. The machines can bend the wire at high speeds and with consistent precision, which results in a higher output of finished products.

Cost Reduction: The use of wire bending machines in the production of kitchenware products reduces the cost of production by reducing labor costs and increasing productivity. This can lead to cost savings for the manufacturer, which can be passed on to the consumer.

Consistent Quality: Wire bending machines ensure consistent quality of the finished products by producing wire shapes that are identical to each other. This ensures that each kitchenware product is of the same quality and meets the required standards.

Auto Link CNC wire bending machine is a valuable machine for creating intricate 2D or 3D shapes with precision, making it suitable for complex applications. Which are used to produce kitchenware products like ergonomic utensil handles, dish rack frameworks, basket and shelf components, cooling racks, and pot/pan handles. With precise bending and customization options, they ensure high-quality and functional kitchenware products.