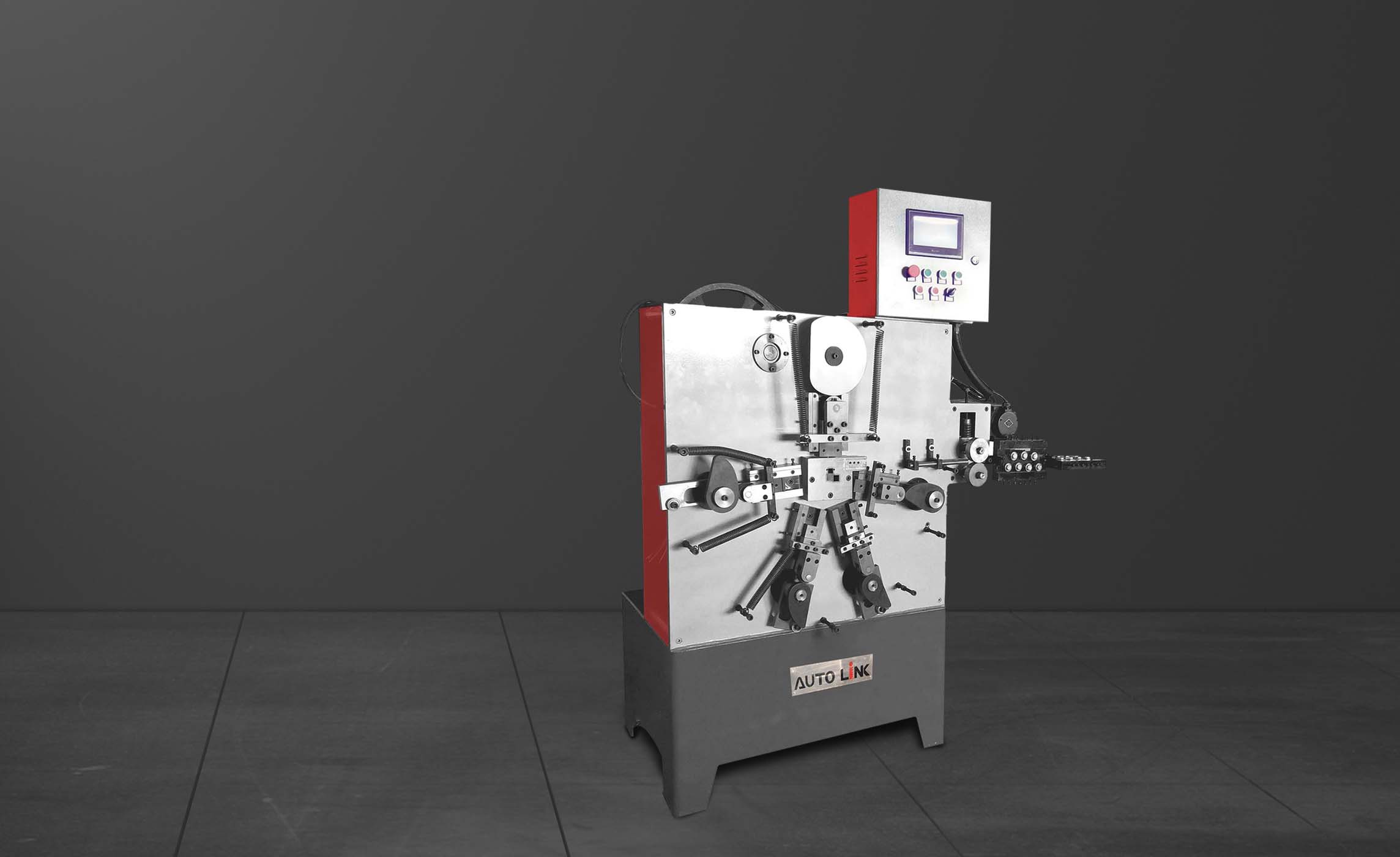

Buckle Making Machine

Product Application & case

Product Details

| Model | AL-SB 3.5 |

| Size | 1.5-3.5mm |

| Strap Size | 12/16mm |

| Feeding Length | 300mm |

| Production Rate | 50-60/min |

| Motor Power | 2.2kw |

| Dimension(L*W*H) | 1700*600*1680 |

| Weight | 750KG |

AL-SB3.5

| Model | AL-SB 3.5 |

| Size | 1.5-3.5mm |

| Strap Size | 12/16mm |

| Feeding Length | 300mm |

| Production Rate | 50-60/min |

| Motor Power | 2.2kw |

| Dimension(L*W*H) | 1700*600*1680 |

| Weight | 750KG |

The CNC buckle-making machine uses CNC technology to control the cutting, bending, and shaping of metal sheets into the desired buckle shape. The machine typically consists of a cutting station, a bending station, and a shaping station.

The cutting station uses a high-speed cutting tool to cut the metal sheets into the desired shape. The bending station uses a series of rollers and dies to bend the metal into the desired buckle shape. The shaping station uses a series of punches and dies to shape and finish the buckle. The CNC buckle-making machine is a highly efficient and precise tool that helps to achieve consistent and high-quality buckle production.

This machine is widely used in the leather goods industry and is suitable for producing a wide range of buckle designs and sizes. The use of CNC technology in buckle making helps to achieve consistent buckle quality, reduced production time, and improved production efficiency.

Features:

- Automation: The machine is fully automated, reducing the need for manual intervention and increasing efficiency.

- High speed: Industrial CNC buckle-making machines are capable of performing cutting and shaping operations at high speed, reducing production time and increasing efficiency.

- Precision: The machine uses CNC technology to ensure high-precision cutting and shaping, which results in buckles that meet exact specifications.

- Versatility: Industrial CNC buckle-making machines can produce a wide range of buckle designs, including simple buckles, complex buckles, and custom buckles.

- Durability and maintenance: The machine is designed for low maintenance, with easy-to-access components and robust construction that is built to last.

Applications:

- Automotive: Industrial CNC buckle-making machines are used to produce buckles for seat belts, airbags, and other safety systems in the automotive industry.

- Military and law enforcement: The machines are used to manufacture high-quality buckles for military and law enforcement equipment, including holsters, vests, and belts.

- Consumer goods: Industrial CNC buckle-making machines are used to produce buckles for a wide range of consumer goods, including backpacks, luggage, and camping gear.Industrial equipment: The machines are used to produce buckles for industrial equipment, such as safety harnesses, cargo straps, and load-securing systems.