5/6 Axis CNC Wire Forming Machine

Application : 0.5-3.8mm Wire Diameter

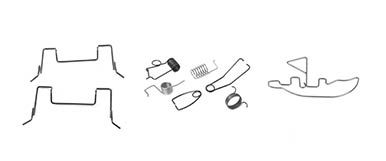

Product Application & case

Product Details

| Model | WF-525R |

| Wire Diameter | 0.5-2.5mm |

| Axis | 5-6 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01mm |

| Wire Feed Rollers Groups | 3 Sets |

| Max.Wire Feed Speed | 100m/min |

| Quill Rotary Axis | 0.4KW |

| Wire Rotary Axis | 2.0KW |

| Cam Axis | 2.7KW |

| Spinner Axis | 0.4KW |

| Wire Feeding Axis | 2.7KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension(M) | 1.3*1.1*1.7 |

| Weight | 1500KG |

| Model | WF-538R |

| Wire Diameter | 1.0-3.8mm |

| Axis | 5-6 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01mm |

| Wire Feed Rollers Groups | 3 Sets |

| Max.Wire Feed Speed | 80m/min |

| Quill Rotary Axis | 0.75KW |

| Wire Rotary Axis | 2.7KW |

| Cam Axis | 4.5KW |

| Spinner Axis | 1.0KW |

| Wire Feeding Axis | 5.5KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension(M) | 1.6*1.3*1.9 |

| Weight | 2500KG |

WF-525R

| Model | WF-525R |

| Wire Diameter | 0.5-2.5mm |

| Axis | 5-6 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01mm |

| Wire Feed Rollers Groups | 3 Sets |

| Max.Wire Feed Speed | 100m/min |

| Quill Rotary Axis | 0.4KW |

| Wire Rotary Axis | 2.0KW |

| Cam Axis | 2.7KW |

| Spinner Axis | 0.4KW |

| Wire Feeding Axis | 2.7KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension(M) | 1.3*1.1*1.7 |

| Weight | 1500KG |

WF-538R

| Model | WF-538R |

| Wire Diameter | 1.0-3.8mm |

| Axis | 5-6 |

| Max.Wire Feed Value | 9999.99mm |

| Min.Wire Feed Value | 0.01mm |

| Wire Feed Rollers Groups | 3 Sets |

| Max.Wire Feed Speed | 80m/min |

| Quill Rotary Axis | 0.75KW |

| Wire Rotary Axis | 2.7KW |

| Cam Axis | 4.5KW |

| Spinner Axis | 1.0KW |

| Wire Feeding Axis | 5.5KW |

| Compressor Air Pressure | 5-6kg/cm |

| Probe | 4pcs |

| Dimension(M) | 1.6*1.3*1.9 |

| Weight | 2500KG |

The 5-axis CNC wire-forming machine comes with a wire rotary. Hence, it shows that the machine can able to attach several tools. As usual, the machine’s working remains the same. The machine helps to build complex shapes of compression, tension, torsion, tower, and flat wire springs.

The input wire is loaded into the decoiler unit with a capacity of 60Kg to 2000Kg. The wire is then straightened by the straightening unit and sent to the wire feeder roller for transfer through the quill rotary. The forming process begins, and if necessary, the holding tool is used to secure the wire during the process. The CNC machine includes various bending tools as needed and can include a spinner action.

Input Materials: Stainless Steel, Aluminium, Brass, Bronze, Carbon Steel, Cold-Rolled Steel, Copper, Nickel, Titanium, etc. The input wire diameter ranges between 0.5mm and 3.8mm.

Input materials: Stainless Steel, Aluminium, Brass, Bronze, Carbon Steel, Cold-Rolled Steel, Copper, Nickel, Titanium, etc.

Applications:

- Electrical industry: electrical components, such as circuit breakers, connectors, and switches.

- Manufacturing of automotive parts: seat frames, door locks, and springs.

- Medical equipment: orthopedic implants, surgical instruments, and dental devices.

- Production of wire baskets and shelves: create wire baskets and shelves

- Consumer products: wire hangers, coat racks, and jewelry.

Available Models: WF-525R & WF-538R