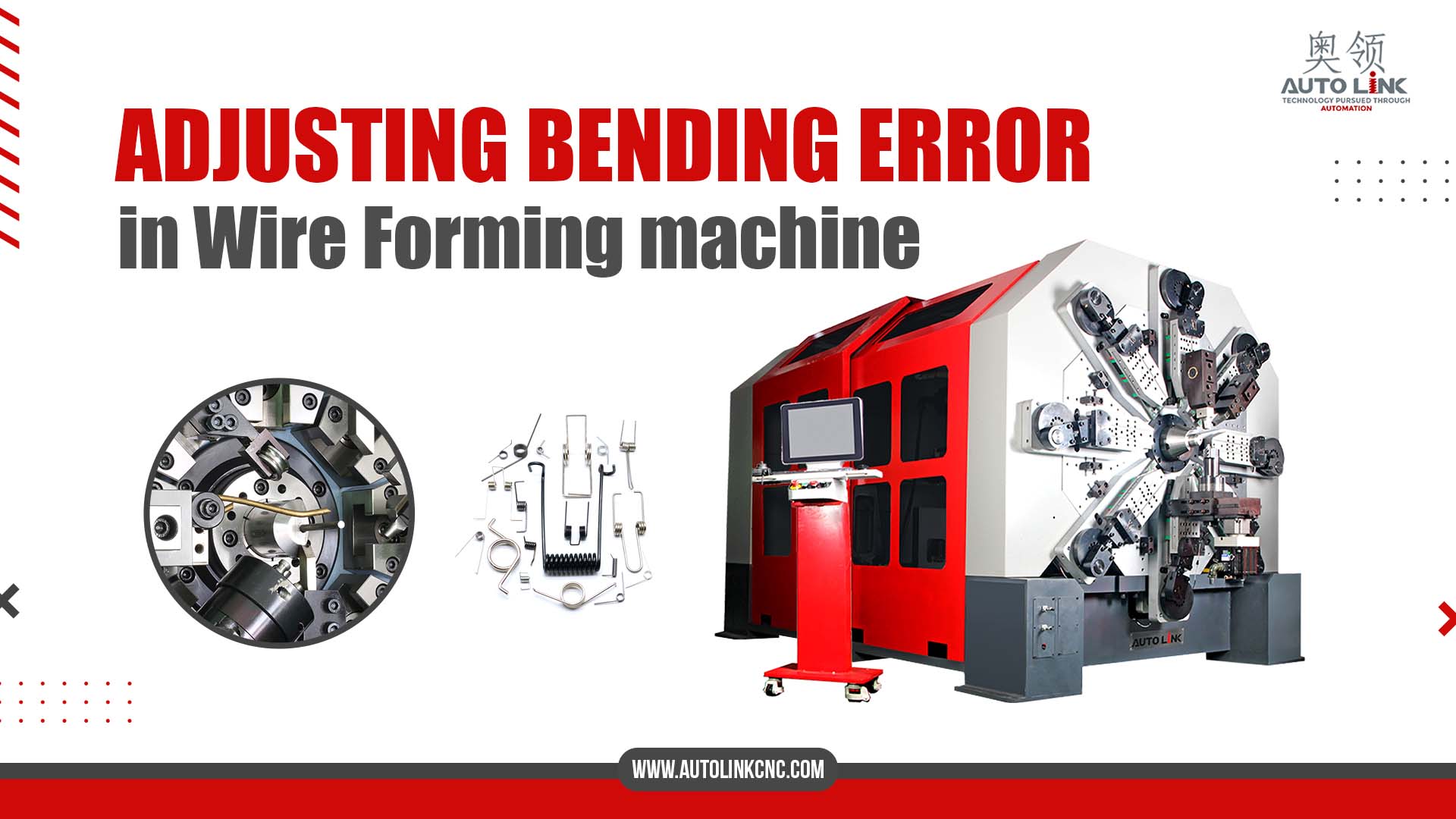

Adjusting Bending Error In Wire Forming machine

The wire forming machine is an efficient, high-precision wire forming automation equipment. Still, we should pay attention to correct operation and equipment conditions during the approach. Otherwise, bending errors are inclined to happen.

How to Adjust bending:

The bending mistake is perhaps an operational error or a problem with the equipment, and the trouble is that it needs to be inspected and dealt with in time. Otherwise, the quality of the following products will be affected.

How to deal with this problem:

Step 1: Check whether the tool of the machine is damaged. If the tool damage causes the error, you should replace the tool to rectify the mistake.

Step 2: If the tool has no damage, check whether there is a problem with the standard of the wire.

Step 3:

- After troubleshooting the above two situations, there is still a specific error in the inclination of the bending part.

- It might be because of the failure of the hydraulic approach in the machine.

- The balance mechanism does not guarantee that the pressure oil evenly enters the left and right cylinders.

Step 4:

- Finally, adjust the operating mode of the wire forming machine to the state of "inching adjustment," and then clear the mold in the device so that the slider can stay on the mechanical stop.

- Then adjust the pressure gauge. In terms of pressure value, the specific method is to compress the head of the dial indicator in the wire forming machine by 3-4 mm, step on the foot pedal to increase the pressure of the system, and check when the pressure is increased, or the system is discharged.

- In the case of the dial indicator's hour hand variation, the operation can be stopped if it reaches the specified value.

Note: Make sure that you make regular maintenance to avoid complexities.