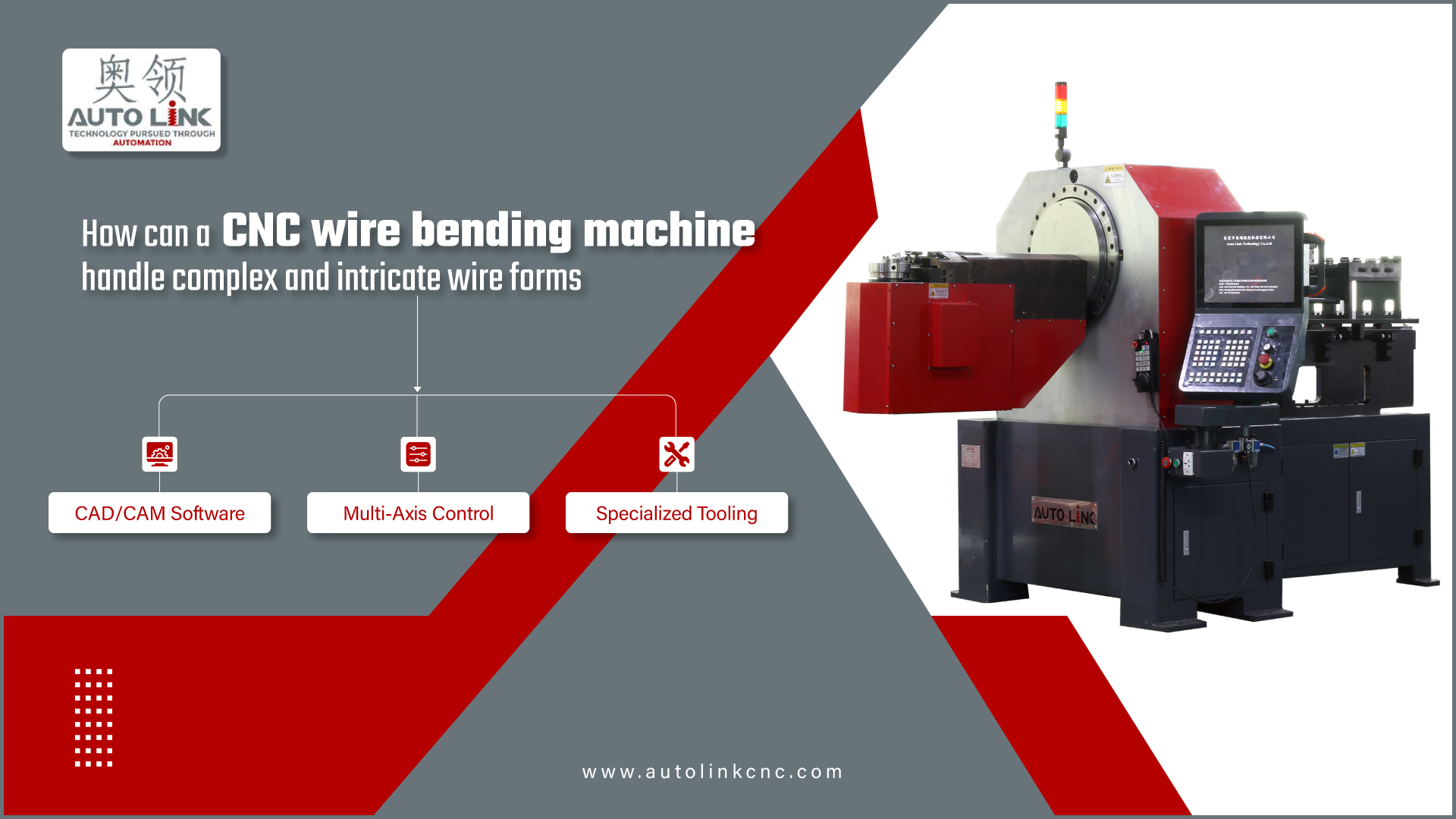

How can a CNC Wire Bending Machine handle complex and intricate wire forms

A CNC Wire Bending Machine is capable of handling complex and intricate wire forms through its advanced features and capabilities. Here's a detailed explanation of how it achieves this:

- Computer Numerical Control (CNC): CNC Wire Bending Machines rely on computer programming to precisely control their movements, allowing them to handle complex and intricate wire forms with accuracy and repeatability.

- CAD/CAM Software: CAD and CAM software is essential for the precise creation of intricate wire form designs, specifying dimensions and angles, and translating them into machine instructions for CNC Wire Bending Machines

- Multi-Axis Control: CNC Wire Bending Machines have multiple axes of control, enabling them to manipulate wire in various directions and planes. This versatility facilitates the creation of complex bends, twists, and shapes.

- Specialized Tooling: CNC Wire Bending Machines utilize specialized tooling, such as mandrels, bending dies, and custom fixtures, to handle complex wire forms. The machine can switch between different tooling configurations for intricate wire shapes

- Automatic Wire Feeding: CNC Wire Bending Machines incorporate automatic wire feeding systems to ensure continuous supply, handle different wire diameters, and maintain consistent tension for precise and intricate bends.

- Real-Time Monitoring and Adjustments: Advanced CNC Wire Bending Machines use sensors and feedback mechanisms for real-time monitoring. They detect shape deviations and enable immediate adjustments for precise wire form creation.

CNC Wire Bending Machines utilize their capabilities to handle intricate wire forms precisely and efficiently. They find extensive use in industries like automotive, aerospace, electronics, and furniture manufacturing, which demand customized wire components.