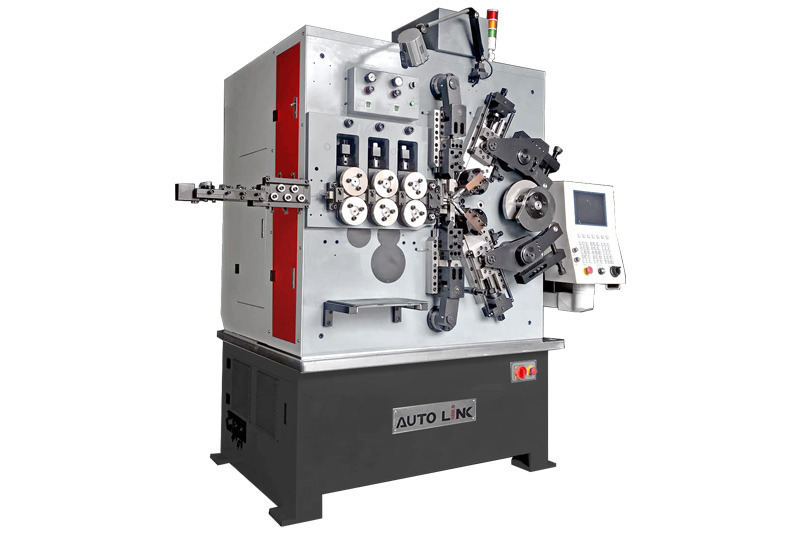

5 Axis CNC Spring Coiling Machine

Application: 3.0-12.0mm Wire Diameter

Product Application & case

Product Details

| Model | SC-560 |

| Axis | 5 |

| Wire Diameter | 3.0-6.0mm |

| Max.Outside Diameter(MM) | 120mm |

| Wire Feeding Rollers Groups | 3 |

| Wire Feeding Motor(KW) | 15 |

| Up Cut motor(KW) | 2.7 |

| Lower Cut motor(KW) | 2.7 |

| OD Control Motor(KW) | 2.7 |

| Pitch Control Motor(KW) | 2.7 |

| Air Pressure | 4-6kg/cm |

| Size | 2150*1600*2300 |

| Weight(KG) | 5000kg |

| Model | SC-580 |

| Axis | 5 |

| Wire Diameter | 3.0-8.0mm |

| Max.Outside Diameter(MM) | 120mm |

| Wire Feeding Rollers Groups | 4 |

| Wire Feeding Motor(KW) | 30 |

| Up Cut motor(KW) | 5.5 |

| Lower Cut motor(KW) | 5.5 |

| OD Control Motor(KW) | 5.5 |

| Pitch Control Motor(KW) | 2.7 |

| Air Pressure | 4-6kg/cm |

| Size | 1440*2320*2400 |

| Weight(KG) | 7000kg |

| Model | SC-5120 |

| Axis | 5 |

| Wire Diameter | 6.0-12.0mm |

| Max.Outside Diameter(MM) | 150mm |

| Wire Feeding Rollers Groups | 4 |

| Wire Feeding Motor(KW) | 37 |

| Lower Cut motor(KW) | 7 |

| UP Cut motor(KW) | 7 |

| OD Control Motor(KW) | 7 |

| Pitch Control Motor(KW) | 4.5 |

| Air Pressure | 4-6kg/cm |

| Size | 1900*3350*2300 |

| Weight(KG) | 12000kg |

SC-560

| Model | SC-560 |

| Axis | 5 |

| Wire Diameter | 3.0-6.0mm |

| Max.Outside Diameter(MM) | 120mm |

| Wire Feeding Rollers Groups | 3 |

| Wire Feeding Motor(KW) | 15 |

| Up Cut motor(KW) | 2.7 |

| Lower Cut motor(KW) | 2.7 |

| OD Control Motor(KW) | 2.7 |

| Pitch Control Motor(KW) | 2.7 |

| Air Pressure | 4-6kg/cm |

| Size | 2150*1600*2300 |

| Weight(KG) | 5000kg |

SC-580

| Model | SC-580 |

| Axis | 5 |

| Wire Diameter | 3.0-8.0mm |

| Max.Outside Diameter(MM) | 120mm |

| Wire Feeding Rollers Groups | 4 |

| Wire Feeding Motor(KW) | 30 |

| Up Cut motor(KW) | 5.5 |

| Lower Cut motor(KW) | 5.5 |

| OD Control Motor(KW) | 5.5 |

| Pitch Control Motor(KW) | 2.7 |

| Air Pressure | 4-6kg/cm |

| Size | 1440*2320*2400 |

| Weight(KG) | 7000kg |

SC-5120

| Model | SC-5120 |

| Axis | 5 |

| Wire Diameter | 6.0-12.0mm |

| Max.Outside Diameter(MM) | 150mm |

| Wire Feeding Rollers Groups | 4 |

| Wire Feeding Motor(KW) | 37 |

| Lower Cut motor(KW) | 7 |

| UP Cut motor(KW) | 7 |

| OD Control Motor(KW) | 7 |

| Pitch Control Motor(KW) | 4.5 |

| Air Pressure | 4-6kg/cm |

| Size | 1900*3350*2300 |

| Weight(KG) | 12000kg |

A 5-axis CNC spring coiling machine is a computer-numerically controlled machine used for the production of springs. It is equipped with five axes of motion, allowing for the creation of complex spring shapes with high precision. The five axes typically include the X, Y, and Z axes for linear motion and two additional rotary axes for added flexibility. The machine operates using a software program that allows the user to input the desired spring specifications, such as size and shape, and the machine will automatically produce the spring to those specifications. A metal compression spring-making machine has two distinct axes: the Wire Feeding axis and the Cam axis. These axes work together to ensure accurate spacing between springs, resulting in higher precision tolerance. By utilizing these two axes, the machine can design the precise shape of the final spring product. The metal compression spring-making machine starts with the user providing the input wire to a decoiler unit with a loading capacity ranging from 60 kg to 300 kg. The straightening unit then effectively removes any deformations in the wire. The wire feeding roller and straightening unit collaborate to prepare the material for coiling. The material is then wound to form the required spring shape. The Wire Feeding and Cam axes regulate the spacing between the springs. The CNC programming unit oversees the operation of the machine, ensuring a smooth and efficient production. This machine can produce both right-hand and left-hand coiled springs.

Input materials: Stainless Steel, Aluminium, Brass, Bronze, Carbon Steel, Cold-Rolled Steel, Copper, Nickel, Titanium, etc.

Applications:

Consumer products: Springs are used in a variety of consumer products such as toys, locks, and furniture.

Industrial machinery: Springs are used in various machines and equipment such as compressors, pumps, and valves.

Medical equipment: Springs are used in medical equipment such as surgical instruments and devices.

Electronics: Springs are used in electronic devices such as switches, connectors, and battery contacts.

Automotive industry: Springs are used in a variety of automotive components, including suspensions, clutches, and brakes.

Aerospace industry: Springs are used in the aerospace industry in various applications, including landing gear, control systems, and actuators.

Available Models: SC-560, SC-580, SC-5120