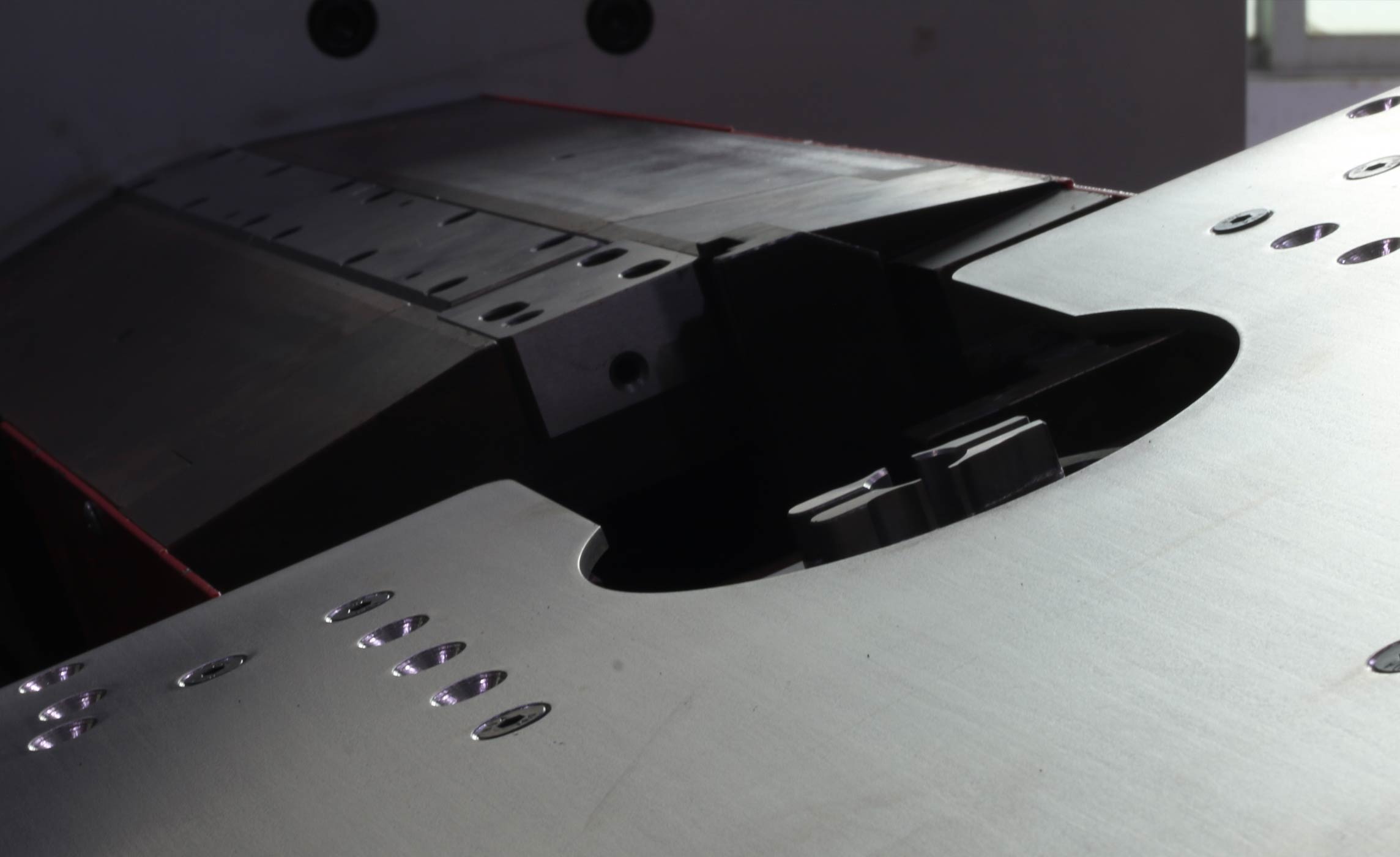

2D CNC Wire Bending Machine

Application: 3.0-8.0mm wire bending parts

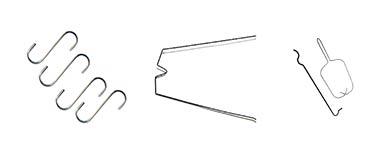

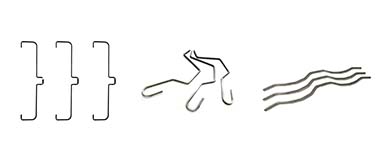

Product Application & case

Product Details

| Model | WB-2D206E |

| Soft Wire | 2-6mm |

| Hard Wire | 2-5mm |

| Wire Feed Roller Groups | 3Groups |

| Wire Feed Speed | 55m/min |

| Bending Accuracy | 0.3mm |

| Wire Feeding Accuracy | 0.1mm |

| Wire Feed Servo motor Power | 2.6kw |

| Bending Servo Motor Power | 2.6kw |

| Cutting Servo Motor power | 1.0kw |

| Inner Bending Up & Down | 1.0kw |

| Voltage | 3P380V |

| Dimension (mm) | 2500*1200*1600 |

| Weight | 700Kg |

| Model | WB-2D208E |

| Soft Wire | 3-8mm |

| Hard Wire | 3-6mm |

| Wire Feed Roller Groups | 3Groups |

| Wire Feed Speed | 55m/min |

| Bending Accuracy | 0.3mm |

| Wire Feeding Accuracy | 0.1mm |

| Wire Feed Servo motor Power | 3.8kw |

| Bending Servo Motor Power | 2.6kw |

| Cutting Servo Motor power | 1.0kw |

| Inner Bending Up & Down | 1.0kw |

| Voltage | 3P380V |

| Dimension (mm) | 2500*1200*1600 |

| Weight | 700Kg |

| Model | WB-2D210E |

| Soft Wire | 4-10mm |

| Hard Wire | 4-8mm |

| Wire Feed Roller Groups | 5Groups |

| Wire Feed Speed | 45m/min |

| Bending Accuracy | 0.3mm |

| Wire Feeding Accuracy | 0.1mm |

| Wire Feed Servo motor Power | 5.5kw |

| Bending Servo Motor Power | 2.6kw |

| Cutting Servo Motor power | 2.0kw |

| Inner Bending Up & Down | 2.0kw |

| Voltage | 3P380V |

| Dimension (mm) | 3000*1200*1600 |

| Weight | 750Kg |

| Model | WB-2D212E |

| Soft Wire | 6-12mm |

| Hard Wire | 6-0mm |

| Wire Feed Roller Groups | 5Groups |

| Wire Feed Speed | 40m/min |

| Bending Accuracy | 0.3mm |

| Wire Feeding Accuracy | 0.1mm |

| Wire Feed Servo motor Power | 75kw |

| Bending Servo Motor Power | 3.0kw |

| Cutting Servo Motor power | 3.8kw |

| Inner Bending Up & Down | 3.8kw |

| Voltage | 3P380V |

| Dimension (mm) | 3000*1200*1600 |

| Weight | 750Kg |

WB-2D206E

| Model | WB-2D206E |

| Soft Wire | 2-6mm |

| Hard Wire | 2-5mm |

| Wire Feed Roller Groups | 3Groups |

| Wire Feed Speed | 55m/min |

| Bending Accuracy | 0.3mm |

| Wire Feeding Accuracy | 0.1mm |

| Wire Feed Servo motor Power | 2.6kw |

| Bending Servo Motor Power | 2.6kw |

| Cutting Servo Motor power | 1.0kw |

| Inner Bending Up & Down | 1.0kw |

| Voltage | 3P380V |

| Dimension (mm) | 2500*1200*1600 |

| Weight | 700Kg |

WB-2D208E

| Model | WB-2D208E |

| Soft Wire | 3-8mm |

| Hard Wire | 3-6mm |

| Wire Feed Roller Groups | 3Groups |

| Wire Feed Speed | 55m/min |

| Bending Accuracy | 0.3mm |

| Wire Feeding Accuracy | 0.1mm |

| Wire Feed Servo motor Power | 3.8kw |

| Bending Servo Motor Power | 2.6kw |

| Cutting Servo Motor power | 1.0kw |

| Inner Bending Up & Down | 1.0kw |

| Voltage | 3P380V |

| Dimension (mm) | 2500*1200*1600 |

| Weight | 700Kg |

WB-2D210E

| Model | WB-2D210E |

| Soft Wire | 4-10mm |

| Hard Wire | 4-8mm |

| Wire Feed Roller Groups | 5Groups |

| Wire Feed Speed | 45m/min |

| Bending Accuracy | 0.3mm |

| Wire Feeding Accuracy | 0.1mm |

| Wire Feed Servo motor Power | 5.5kw |

| Bending Servo Motor Power | 2.6kw |

| Cutting Servo Motor power | 2.0kw |

| Inner Bending Up & Down | 2.0kw |

| Voltage | 3P380V |

| Dimension (mm) | 3000*1200*1600 |

| Weight | 750Kg |

WB - 2D212E

| Model | WB-2D212E |

| Soft Wire | 6-12mm |

| Hard Wire | 6-0mm |

| Wire Feed Roller Groups | 5Groups |

| Wire Feed Speed | 40m/min |

| Bending Accuracy | 0.3mm |

| Wire Feeding Accuracy | 0.1mm |

| Wire Feed Servo motor Power | 75kw |

| Bending Servo Motor Power | 3.0kw |

| Cutting Servo Motor power | 3.8kw |

| Inner Bending Up & Down | 3.8kw |

| Voltage | 3P380V |

| Dimension (mm) | 3000*1200*1600 |

| Weight | 750Kg |

The 2D CNC wire bending machine is one of the futuristic machines which produces the best 2D output forms. Like the CNC Wire Bending normal working process, it pursues the work and forms the output. Hence, it is not necessary to prefer a higher rate of CNC machines. Initially, the user gives metal or other suitable input to the de-coiler. The coiled wire is straightened using the wire straightener. 2D wire bending machine includes a straightening unit and feeding mechanism. The vertical and horizontal plane straightening units are available within the machine.

Then, the machine feeds the wire to the wire feeder with a roller. Hence, the wire guide of 800 mm long ensures the 360° rotation for the wire bends. The wire was then bent according to the customer's requirement. The bending part consists of two parts: inner and outer bending. Therefore, the output wire bend on both sides. It is then cut when the preferred shape is formed. The servo motor ensures the working of the wire bending machine effectively.

All these actions are performed based on a CNC programming unit. The CNC machines interfaced with English and Chinese languages. Therefore, the machine manufactures language preferences concerning the customer's needs. Metal wires can form all kinds of 2D structures using this 2D wire bending machine. Cutting, chamfering, threading, end-forming, punching, pick & place tool can perform bending mechanisms. Hence, the production rate increases with programmed processes. This makes the wire-bending machine very efficient

Input materials: Stainless Steel, Aluminium, brass, bronze, carbon steel, cold-rolled steel, copper, nickel, titanium, etc.

Applications:

The above image also shows the output samples. Here is the list of industrial and commercial applications.

- Steel S-hook

- Metal tray handle

- door handle

- ceiling hooks

- Rack hooks

- Triangle percussion musical instrument

- Steel Eggbeater

- Bucket handle

- Steel door handle

Available Model: WB-2D206E,WB-2D208E,WB-2D210E